Extruded Heat Sink Manufacturing Process

The principle of Extruded heat sink is to use the melting furnace to heat the aluminum ingot at high temperature and extrude the aluminum rod, then inject the aluminum rod into the mold with different tooth shapes or structures to make the initial structure of the heat sink.

Then carry out post-processing (such as cutting size, CNC, grooving, polishing, drilling, riveting materials, trimming, sandblasting, wire drawing, cleaning and surface treatment), Assembling and packaging after completion of inspection.

Extruded Heat Sink Advantages

- Low price, low mold cost and large output.

- Aluminum alloy, its metal properties are acid and alkali resistance, corrosion resistance, low density and light weight.

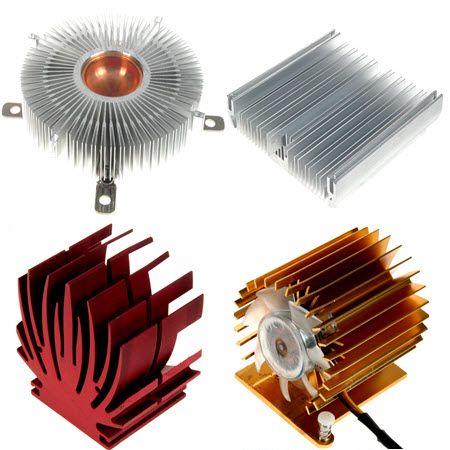

- Complicated shapes can be made under the extrusion specification: sun flower heat sink, etc.

- After aluminum extrusion production, the surface is smooth and glossy, and the post-processing surface treatment can be made in different colors: industrial computer casings, etc.

The Main Application Range of Extruded Heat Sink

IGBT devices, welding equipment, electrical equipment, high-power semiconductors, laser systems, renewable energy, factory automation, thermoelectric modules-TEC, uninterruptible power supply systems, AC welding switches, power rectification equipment, power rectification equipment.

Traction Control Motor Drive Cooling Industry: Large heat sinks.

Extruded Heat Sink Production

- 1. Find out if there is a similar Extruded heat sink according to the design drawings, and CNC machining can be carried out according to the designed keyhole. 2. If there is no extrusion similar to the drawings, we will assist in evaluating the feasibility of mold opening.

- Make minor adjustments to facilitate production, and then provide to customers for confirmation Adjusted design drawings.

- Mold design and manufacture.

- Production processing and surface treatment.

- The product is complete.

- Gallery